We have a delta ROV winch. Now that we’re trying to operate it, It starts to rotate and stop in a second. The software displays the warning “Gen Fault”. But the software shows the rotation movement. So the encoders are working. What is this Gen fault? Can you please resolve this issue as soon as possible?

Hello,

Did you use the winch for any amount of time or it started doing this right away?

Sometime wires can get loose during transport.

What you describe is the motor starting to rotate but failing to receive signal from one of the hall sensors.

The encoder signal comes from a different set of wires.

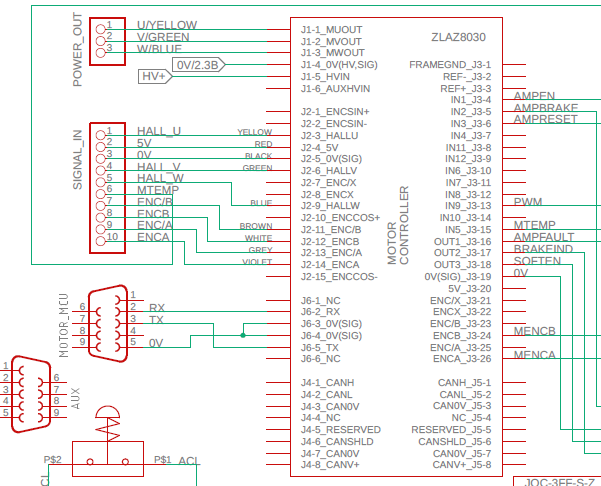

On the winch controller there is POWER OUT to the winch and SIGNAL IN from the winch.

The SIGNAL IN connector pins 1,2,3,4,5 are for the HALLs, please open the box and check that you have continuity from the DB-15 to the end of the 10-Pin cable going to the winch.

Let me know what you find.

Regards,

Delta ROV

We had used the winch once to spool one tether onto it a few days after we received it. It was working fine at that point in time. After that, we tried using it again a few days ago, when this issue was observed.

We checked the continuity of the wires from the DB-15 connector motor controller all the way to the other end of the 10-pin cable going to the winch and there are no issues.

It seems like it could be similar to the issue that you had observed during testing - DROV-INV-2022012101 IROV Technologies Pvt. Ltd - #18 by DeltaROV

where the hall sensor wires had come disconnected inside the motor. You mentioned in that post that you had used some diagnostic software to check the hall sensor signals. Can you please share that software with us so that we can check this? Or if you have any other recommendations, please let us know.

Hello,

I am very sorry this is happening, we did try the winch extensively after our repair but it seems the motor has an issue and overheating. This is the first time this has happened, our other winches do not have this issue.

The motor controller software is here: Dropbox - DCH_EN_V1.2.zip - Simplify your life

You will need to connect your laptop to the serial port in the back of the winch controller.

That said, I am sure its the motor so I will contact the supplier on Monday and organise a replacement to be shipped out ASAP.

Regards,

Etienne

Once you have it connected up with a serial cable and installed the software, let me know via email and we can do a remote connection.

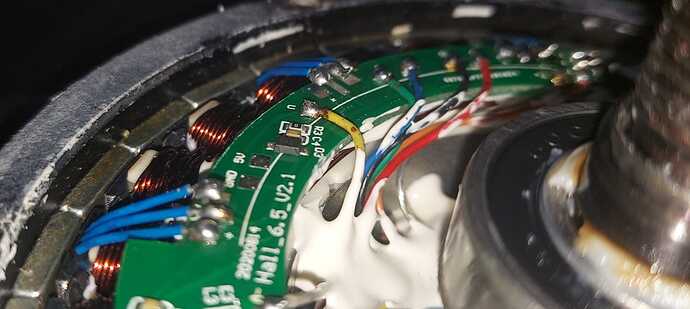

If its the same problem again, you can open the motor and take some pictures. Re-solder the wires will get you going again but I suggest you put epoxy on them.

Alternatively you can ship the winch back to us for servicing.

We will get back to you on Monday to diagnose the problem further.

Meanwhile please initiate the motor replacement. I will get back to you on whether we can replace it ourselves if you can provide us with disassembly instructions or whether we can ship the winch back to you.

Ok, alternatively, if you apply 0 and 5V on the SIGNAL IN connector going to the motor and put the multi-meter on 0V and HALL_U and turn the winch drum you should see the voltage 0V and 5V appear on and off. You can test each HALL like this which might be a faster way to diagnostic then using the software.

Yes, we have tested the same. Where we only get one of the hall sensor outputs on and off. So, what’s the next step?

Hello,

This confirms that the HALL wires need to be re-soldered.

I have been speaking with the manufacturer who advises to resolder and reduce the current to the motor to avoid re-occurrence.

They insist the motor is good.

Regards,

Etienne

Meanwhile please do the replacement for the motor. Because we don’t want to happen once again

hello, it appears a reply was deleted

To remove the motor.

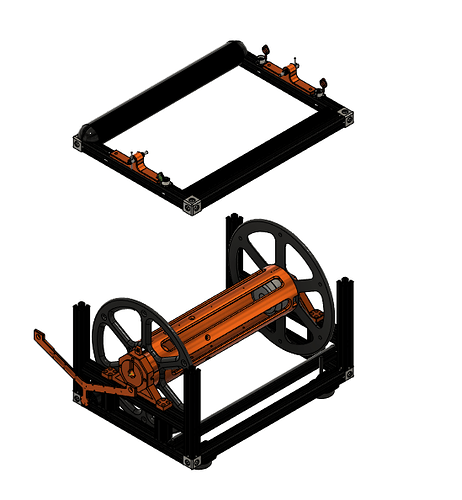

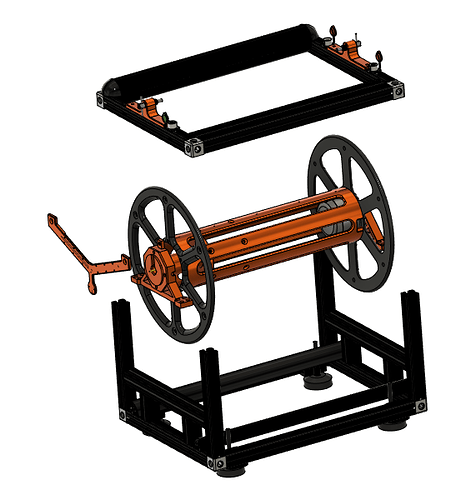

Step 1: Disconnect the fiber and remove the fiber guard.

Step 2:Remove the top assembly.

Step 3: Remove Drum assy. (be careful of the fiber)

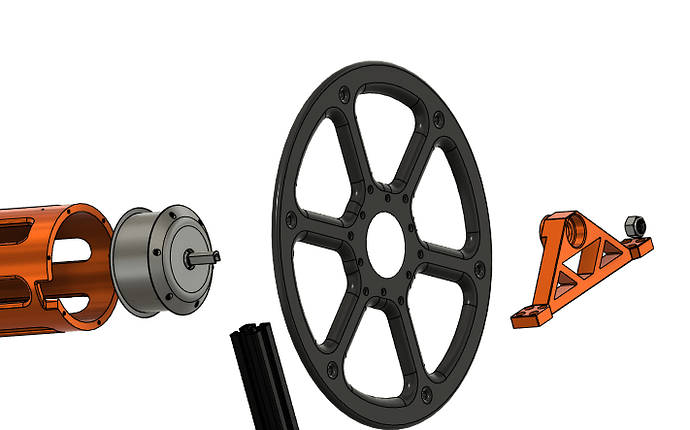

Step 4: Remove Motor nut.

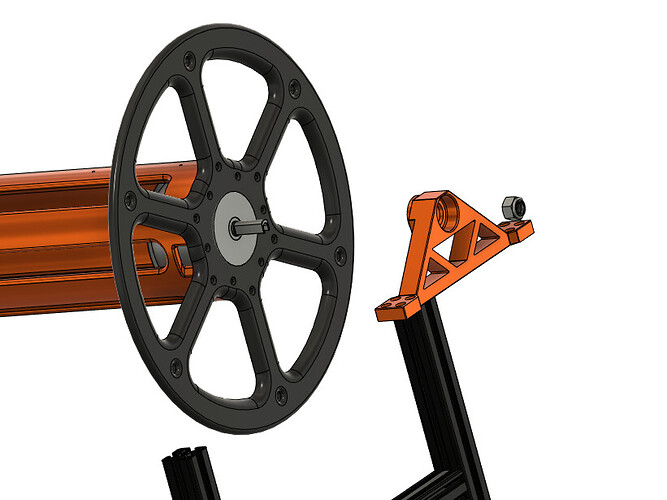

Step 5: Remove motor bracket.

Step 6: Remove drum drum side.

Step 7: Remove motor.

Just opened the motor and found that many of the wires are desoldered. I think the motor heating is causing the problem

Yes this is what is happening.

Please resolder and test, then I will log in remotely and adjust the controller so that we reduce the current to the motor.

Can you confirm that all the coil is uniform color? Nothing blackened.

We have fixed the wires, can u program the controller to reduce the current? Or send the instructions to do so

We have the following programming cable for programming is it ok?

should be fine as long as its detected by windows

send me an email for remote connection

I have shared the code. Please do the programming